Improve process

What is process management?

Process management could be one of the most controversial management methods.

Some see it as a source of bureaucracy. Others see it as a world cut off from reality. Still others think that process management is only relevant for large companies and global corporations. There are also those who think about the processes only on the days when the auditors visit. However, in many companies the process management approach is well known and serves as an instrument for improving efficiency and profitability. Processes are identified, analyzed, improved.

Why streamline processes ?

- regular problems on an issue

- customer complaints are recurring

- limping efficiency,

- delivery delays,

- regularly not enough product in stock

- tired of "extinguishing fires"

- etc.

No matter how careful the company's process planning is, it is not uncommon for business to suddenly run out of resources to provide all operational activities. It is necessary to hire specialists to solve the task. The company must enter into an outsourcing agreement. This opens up great opportunities not to involve your resources above the planned load or to attract resources that will not have a return in the long run, and to look at everything "from the sidelines". Should a small business do process management? And if so, where to start ?

First of all, consultation and clarification of wishes.

Outsorcing

Getting acquainted, competency review. Evaluates the possibility of mutual cooperation from a professional point of view. Company quality standards, control ability, different understandings and experiences, different cultures.

Processes evaluation

Separate process analysis in 3-4 h

In a small company, usually about 10 or ten processes manage to show the logic of the company's operation well enough. For instance,

- How to ensure delivery time

- Reduction of customer claims,

- Order tracking,

- Transport delay

- other

Quality management / logistics in 1-2 days

There may be a greater need for solutions and an improvement plan in one of the company's areas of activity! Then we choose to audit the Quality Management or Logistics Process in 1 day.

Extensive comprehensive process review and analysis or mini audit will give a complete insight into all key areas of activity on Day 2.

Supplier evaluation

It is important to choose partners, suppliers and build better relationships and terms of cooperation with existing ones. 15 years of experience in this field.

You can choose to review specific issues or complete process testing. This is described in the "Process Audit" section.

The result of cooperation - process improvement and creation of new processes

After any audit and process review, the logical step is an ACTION PLAN. Improvements often remain "on paper" due to lack of resources or expertise. Therefore, it is worthwhile to understand at the beginning of the process audit who, how, what will control and manage this plan. I can offer this outsourcing and lead the planned improvements to their stable operation. Has experience and competence. Creating NEW PROCESSES, consulting in existing ones and participating in their implementation is the essence of this service (one-time / LONG-TERM).

Liga Logina

"... Schneider Electric named one of the Fortune's World's Most Admired Companies for the third year in a row January 28, 2020 · 3 min read."

Experience

- Management of the company

- Sales and

- Key customer relationship management

- Customer satisfaction expert

- Logistics management, indicators

- Supplier Quality Management and Logistics Auditor 15 years,

- Supplier Cooperation Expert

- Internal audits

- Team management, coordination, cooperation

- Marketing, advertising

- Potential risk management

- G8D trainer, 5W method expert

I have gained invaluable experience in arranging the company's processes quickly, efficiently and performed audits of about 40 suppliers according to the Schneider method. I also participated in internal audits of CSP (Schneider Production System) which is close to the standards of the automotive industry and is one of the most detailed in general (who has encountered it certainly knows).

NO of my audit assessment it was decided whether to cooperate with the supplier or not Schneider globally. The results were placed in a global company system. Improvement actions were also taken based on the analysis of the result. The EU monitored them and helped implement them.

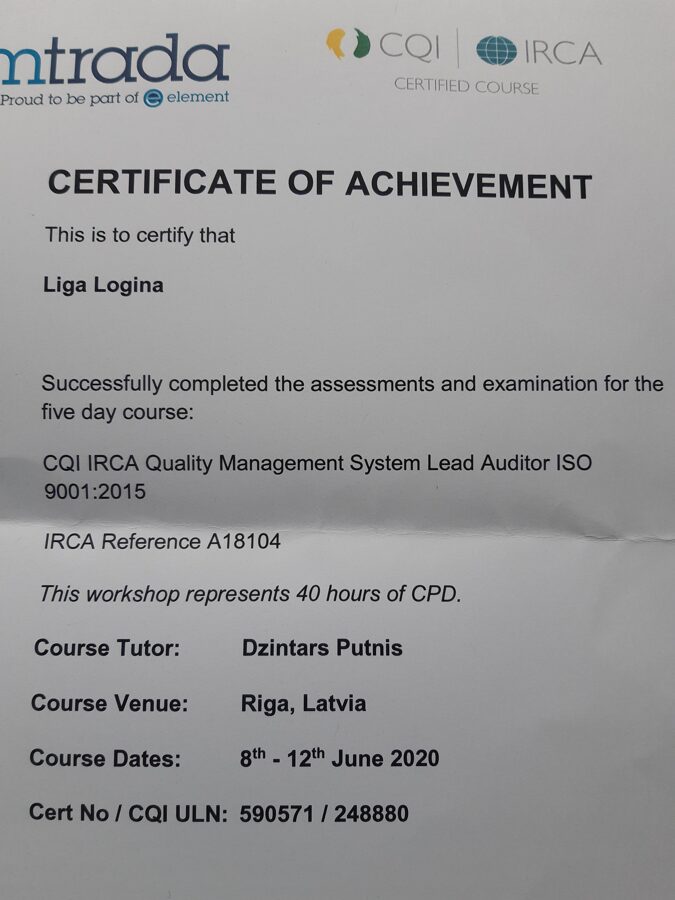

ISO 9001-2015

ISO (issued by IRCA) lead auditor certificate 9001-2015 for passing the exam.

Lots of other courses and seminars during work carrier years.

VISION More streamlined, improved processes in small and medium enterprises LV and EU.

MISSION To work more efficiently and meaningfully. Evaluation of quality management, logistics and third-party processes within a few days. The action plan and its implementation will provide cost savings, improved workforce and customer satisfaction, efficiency, and incentives to monitor processes.

GOAL To create an understanding and evaluation of how effective processes provide an additional basis for growth and development.

Latvian standards clearly define Advisory Services - Consulting and related services, the nature and scope of which are agreed with the client and which are intended to increase the value of the organization's management, risk management and control processes and improve them without the internal auditor assuming management responsibilities. Such services may include, for example, counseling, advice, facilitation and training.